Hey guys. This is Joshua McMillan, and this is your week 6-7 blog post.

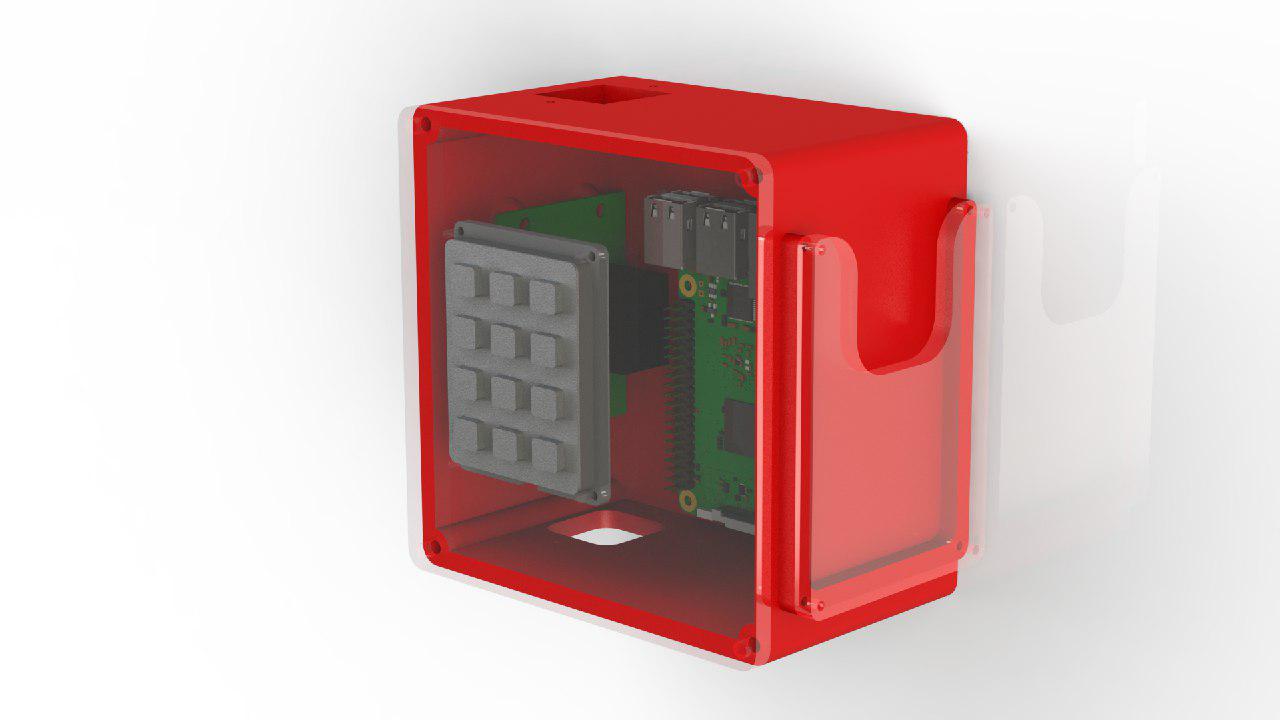

So, the adventures of creating a fully functioning machine access tracking system continues. We have faced some challenges but we faced them with a sense of determination that knows no bounds. The hardware team produced the final design of the electrical enclosure in solid works.

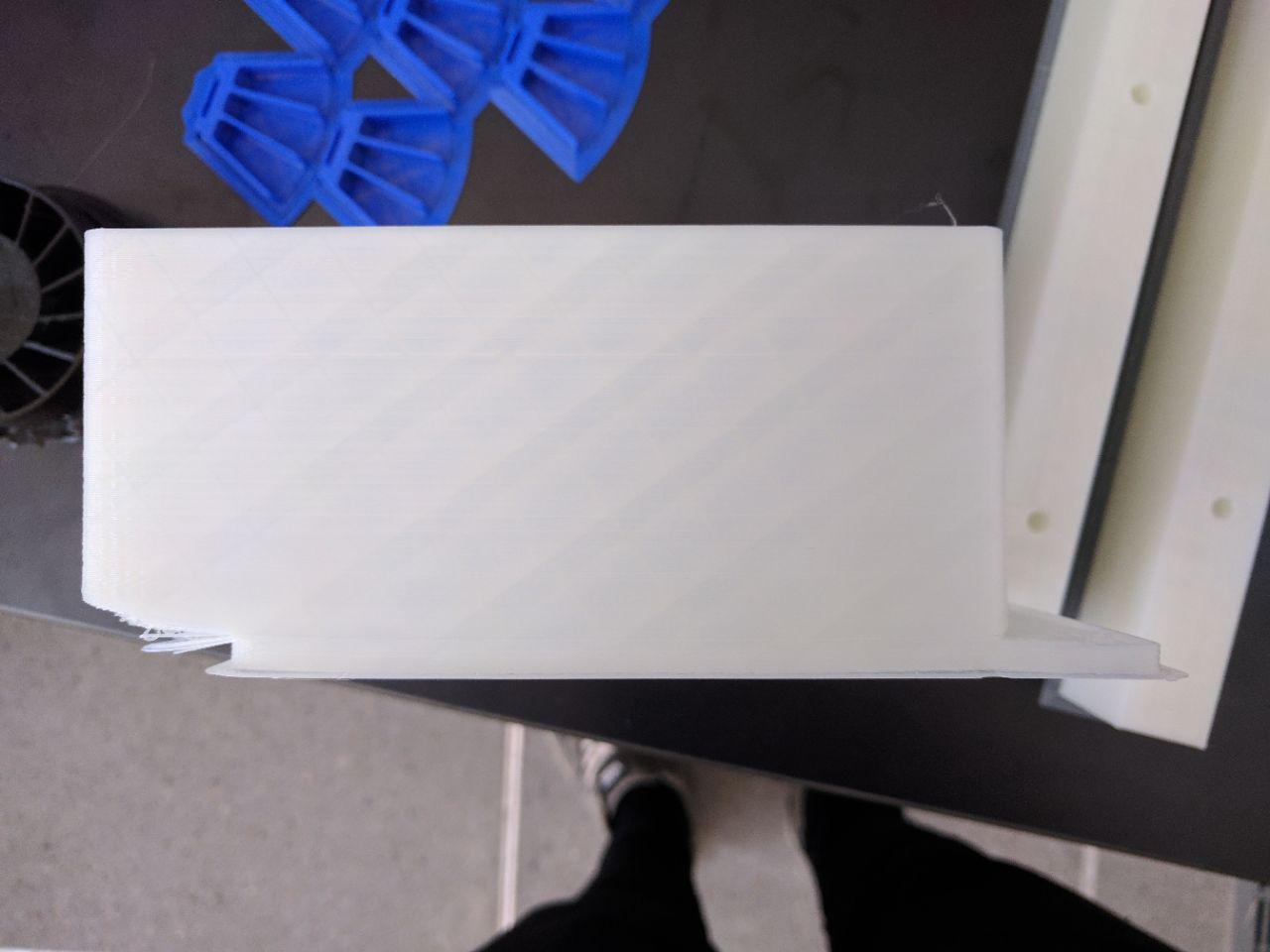

One of the biggest challenges for the hardware time was vanquishing the forces of darkness that seemed to be halting our progress on the 3-D printing of our electrical enclosure. The fruits of our labor seemed to fall short of glory.

^This was our second attempt at printing the enclosure. However, on the third attempt, Stefan was able to overcome our problems by printing the enclosure at his place.

TADA! This enclosure is looking good! The front and side pieces were laser-cut out, and the enclosure is now only missing the electronic parts.

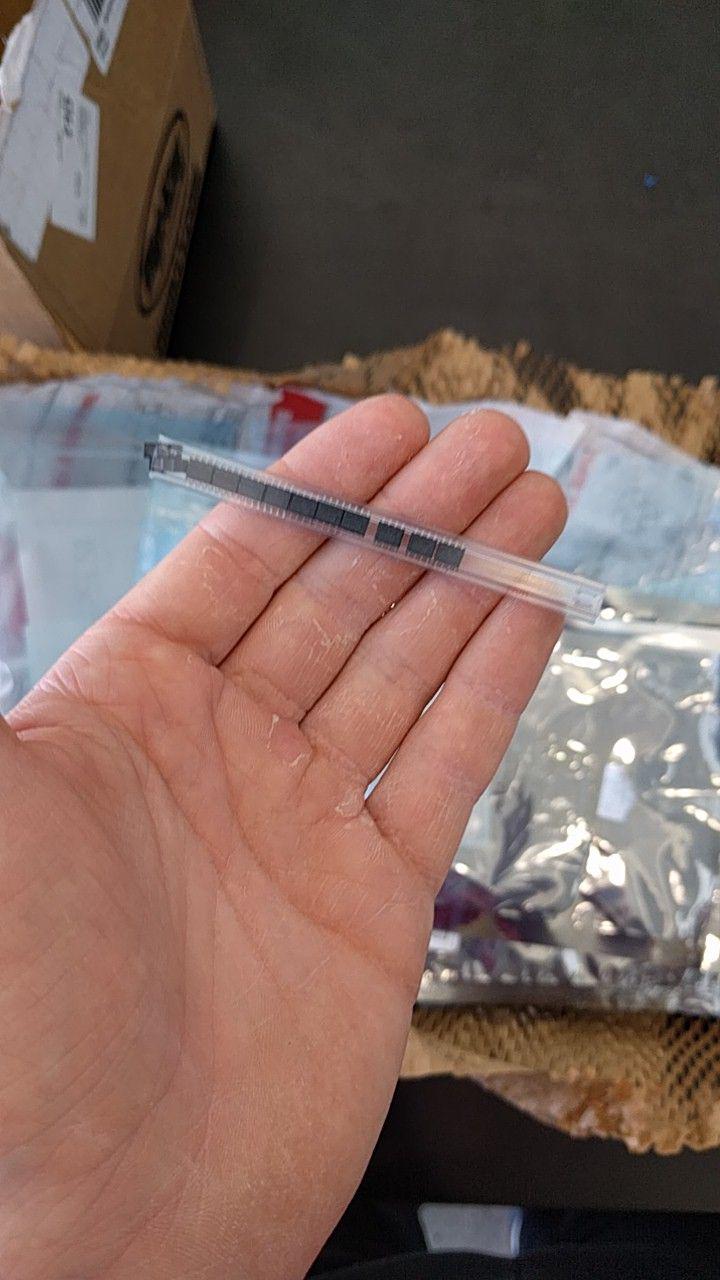

In other news, many of the parts that were required for us to finish our machine access tracking system finally came in. These parts included a 250 foot cat-6, 1kohm resistors, an Eeprom and temperature sensors.

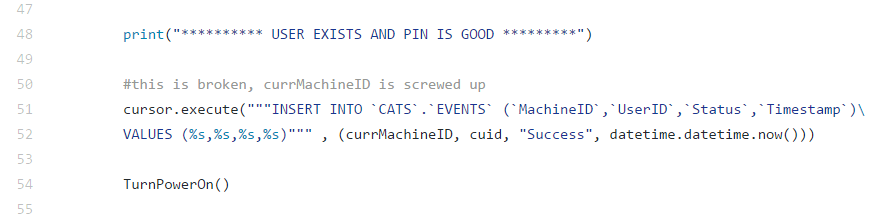

The software team has developed an optional two-factor Authentication system. However, there are a few lines of code are giving us trouble. The lines 50-52 are not executing correctly.

The SQL Machine Table was designed for the two factor Authentication system. If the machine Int is 2, the Pin and ID is required. If it is 1, the PIN is mandatory. If it is 0, then no keypad is required, just the ID.

USER SQL

ID | PIN | OPT

1 | 1111 | 1

2 | 2121 | 0

3 | 4123 | 1

4 | 6134 | 0