REINVENTING AN ANCIENT ART

Applying origami to material science manufacturing

By: Joe Wortkoetter

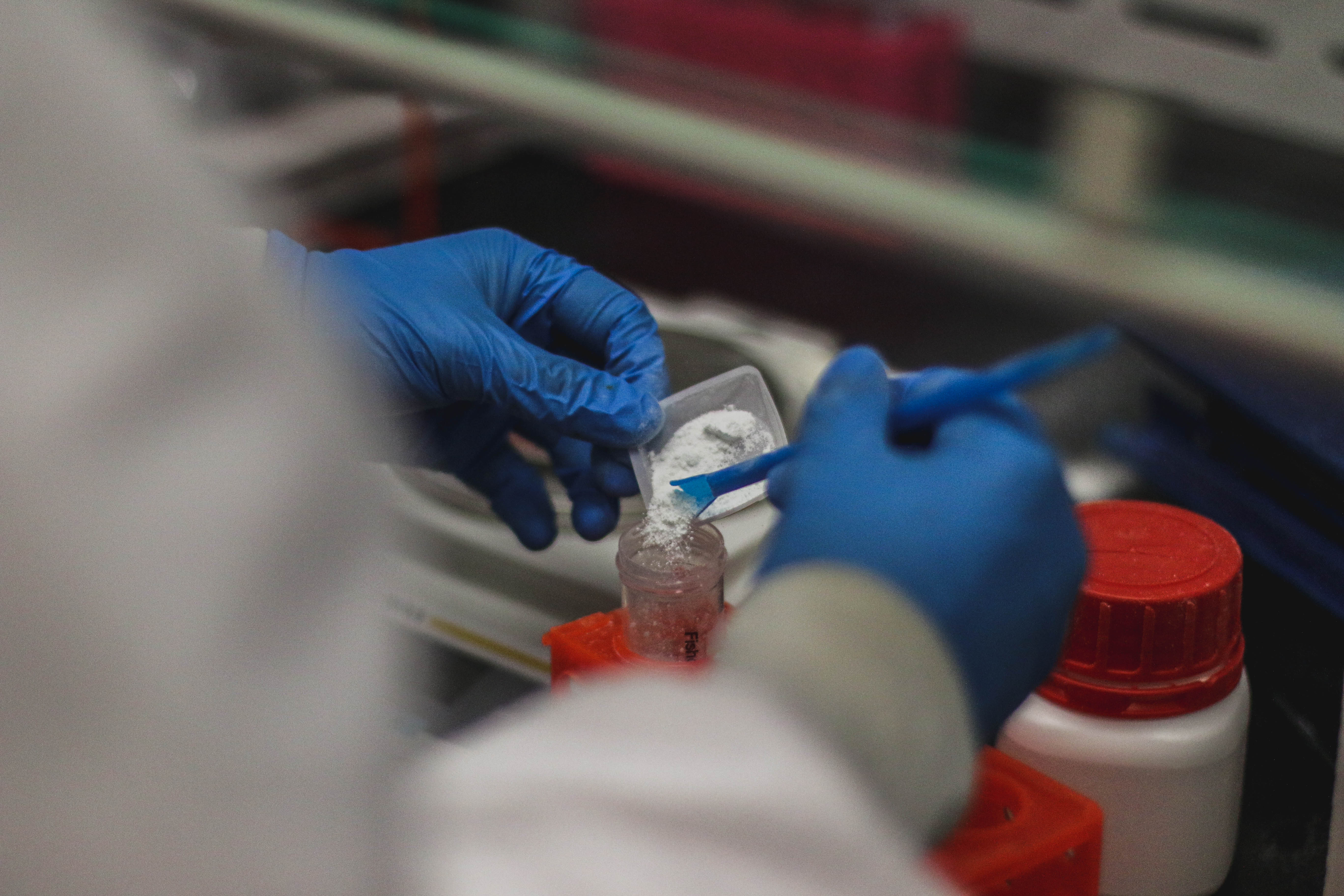

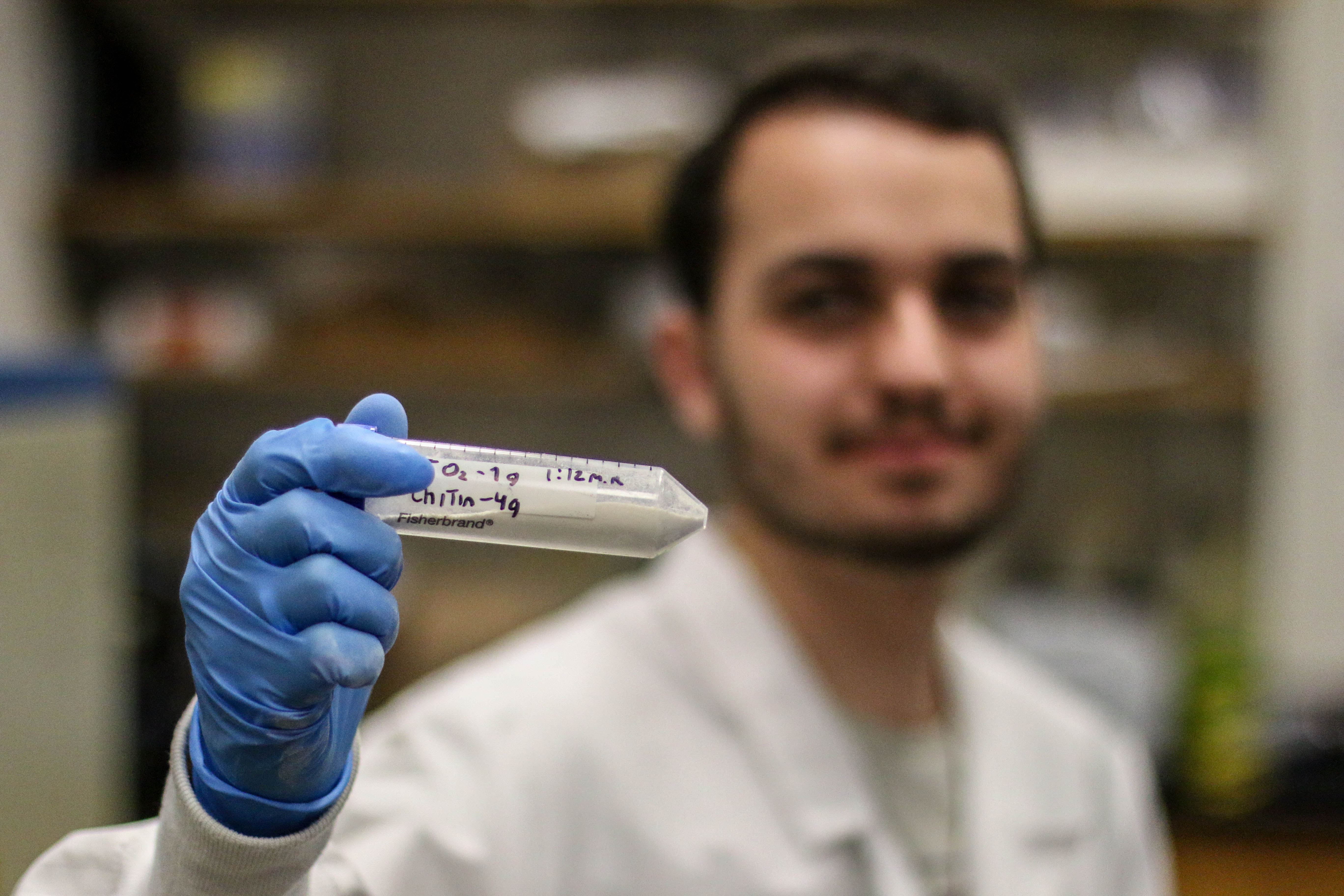

The ancient art of paper-folding, or origami, utilizes simple techniques to transform a two-dimensional piece of paper into a complex, intricate, three-dimensional structure. Though traditionally used for ornamental artwork, students in the Origami-Inspired Manufacturing of Composite Parts Creative Inquiry took a more functional approach with origami. This Creative Inquiry team utilized origami in the manufacturing of metal carbide devices. Besides offering a creative manufacturing process, the team aims to replace the non-renewable, petroleum-based carbon used in the synthesis of carbides with carbon obtained from a renewable resource, paper. The team, led by Dr. Rodrigo Martinez-Duarte, assistant professor in the Department of Mechanical Engineering, expects to reduce the cost of this process and reduce the dependence on petrochemicals. Knowing that a number of bio-polymers combined with metal nanoparticles can be heated to form metal carbides, the team focused on using cellulosic paper as the carbon source. The team decided to use origami-inspired techniques to shape the paper in order to manufacture these devices. Although many different kinds of paper exist, the team uses filter papers, which are 100% cellulose and commonly used in the lab.

They then use origami techniques to fabricate a number of shapes. After infiltrating these shapes with metal nanoparticles, the composite is heated to high temperatures to form a metal carbide structure. According to Martinez-Duarte, “As you start heating the mixture, around 900° C, the paper will carbonize. As you keep increasing the temperature, you can induce the metal nanoparticles to react with the carbonized paper such that you can get metal carbides.” While this synthesis method has proven to be successful, viable manufacturing methods have to be produced; hence the introduction of origami. Think of an origami crane: instead of machining metal carbides into complex shapes, the team is in the process of determining the exact parameters that will enable this novel fabrication process for the fabrication of carbide shapes featuring thin and complex cross sections. For Josh Flach, junior mechanical engineer, the preliminary tests done by the team have proven the process to be successful and worthy of further investigation. “This project was really the combination of several ideas and projects so it’s rewarding to see it all come together and get confirmation that it works,” Flach said.

With metal carbides playing such an important role in many manufacturing processes, research into cheaper production methods could prove extremely beneficial. Reducing dependence on petrochemicals in the process would prove to be not only more environmentally friendly, but also cost efficient. While the task of finding alternate production methods may seem never-ending, this Creative Inquiry teams plans to tackle it head-on, one step at a time.