Taking a Shot at Better Biopsy Needles

by Sarah Dorsey

Needles are no fun. No patient enjoys a shot—even less, a biopsy procedure. In animal and veterinary sciences, biopsy needles look similar to large, borer tools which pose several issues when needing to collect tissue samples from a precise area of an animal. With that in mind, Dr. Heather Dunn in the Department of Animal and Veterinary Sciences patented her method of collecting animal biopsy samples with a small needle rather than the more common, large borer tool.

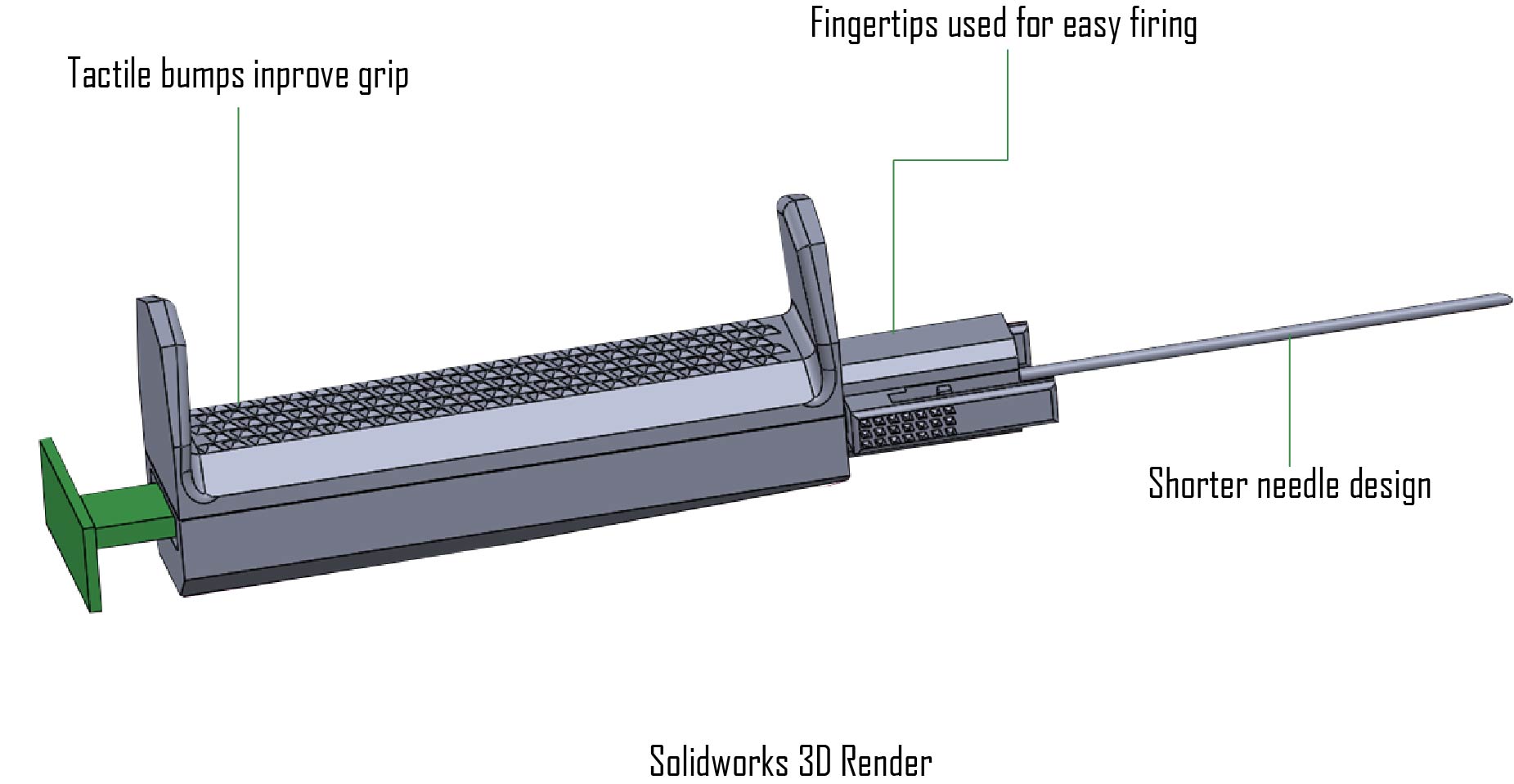

3D Printed Grip Prototype

Dunn and Dr. Jeremy Mercuri, in the Department of Bioengineering, launched the Animal Model Tissue Biopsy Device Design Creative Inquiry project seeking to improve the device. The team worked to understand the needs for the device and its users and designed a potentially marketable solution.

To begin, the team thoroughly assessed the old device and identified unappealing characteristics. The issues included: lack of a tactile/grip mechanism; the existing grip was uncomfortable and made taking biopsies difficult; and the needles used were too long. After watching the device in action and interviewing Dunn for a customer’s perspective, the team set design goals based on feedback regarding desirable device characteristics and existing problems.

After discussions, the team decided to completely revolutionize the new needle’s shape, creating a reusable hand grip for better comfort and control. The team designed each component and printed prototypes in the Watt Family Innovation Center’s Student Makerspace. Creating prototypes using three-dimensional printing technology was essential for the team’s ability to touch the device parts and iteratively design them at a low cost.

Over the course of the project, the team has run the gamut of problems. “The biggest engineering challenges faced by the team were the design of the internal mechanical components and getting them to fit together and function properly and repeatably,” Mercuri said. The team must ensure that everything is perfect since a medical device and human or animal life is involved. The team conducted mechanical tests to ensure durability which is essential for technical and safety documentation needed by the Food and Drug Administration. Evaluation of cost-effective manufacturing processes for mass production is the next step for the team.

This interdisciplinary project offers a glimpse at engineering education of the future. “I am excited that undergraduate students are solving this problem. It is great to have one team give another team problems to solve. This just doesn’t happen in a traditional classroom,” Dunn said. This Creative Inquiry project is not only making scientific strides but helping the students make personal strides. “This is my first undergraduate experience that I joined my freshman year. This CI has pretty much been the basis of all of the R&D skills I’ve used since then,” Jacob Garland, a junior bioengineering major, said.

This interdisciplinary project offers a glimpse at engineering education of the future. “I am excited that undergraduate students are solving this problem. It is great to have one team give another team problems to solve. This just doesn’t happen in a traditional classroom,” Dunn said. This Creative Inquiry project is not only making scientific strides but helping the students make personal strides. “This is my first undergraduate experience that I joined my freshman year. This CI has pretty much been the basis of all of the R&D skills I’ve used since then,” Jacob Garland, a junior bioengineering major, said.

Once veterinary professionals are comfortable with the design and can use it safely, the project will remodel the device for human cancer biopsy applications. Mercuri thinks that the team’s design provides better ergonomics than other devices on the market, and that the new device may aid in the accuracy of the biopsy placement and help obtain more reliable tissue samples.

They work hard to make this device a manufactured reality, committed to lowering costs, reducing pain and getting better tissue samples one shot at a time.